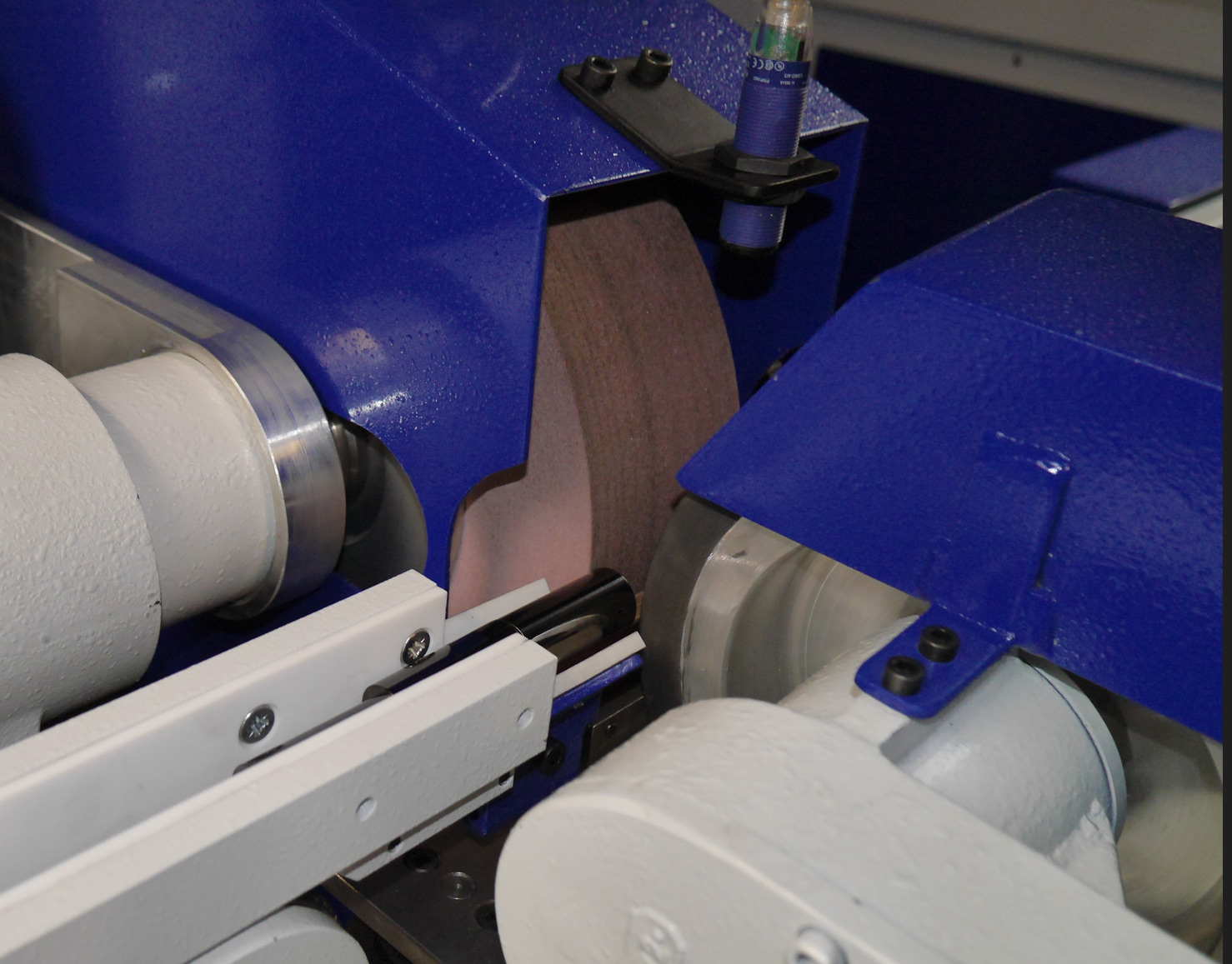

TMUA, spécialiste des systèmes d'abrasion

Soucieux de votre satisfaction, nous nous adaptons à votre cahier des charges pour répondre au mieux à votre besoin.

Secteurs d’activité qui nous demandent

des machines abrasives

Maroquinerie

Tonnellerie

Métallurgie, industrie

Aéronautique

Médical

Bijouterie

TMUA fabrique des machines abrasives pour ses clients en France mais aussi à l’étranger

TMUA dispose d’un catalogue de machines abrasives standards mais également des

machines spéciales afin de répondre aux demandes spécifiques des clients.

Toute demande est réalisable, n’hésitez pas à nous contacter.

Afin de couvrir tous vos besoins, TMUA propose une large gamme de machines de polissage polyvalentes et simples

Notre équipe réalise toutes les prestations pour tous types de secteurs : étude suivant le cahier des charges établi par le client, fabrication, montage, électricité, automatisme et implantation sur site.

Nous disposons sur parc d’un certain nombre de ponceuses d’occasion. Toutes nos machines d’occasion sont vendues révisées avec une auto-certification de type CE

TMUA vient de racheter les actifs incorporels techniques, mécaniques et électriques de la Société SPMS Supramatic

Nous sommes en mesure de répondre à toute demande concernant les produits SPMS telles que des machines de superfinitions et des machines d’ébavurages, pièces détachées et SAV.

AM2S est le fournisseur des produits abrasifs de l’ensemble des machines de TMUA

Les sociétés TMUA et AM2S sont complémentaires. TMUA fabrique les machines de systèmes d’abrasion, et AM2S fournit l’ensemble des produits d’abrasion

TMUA est distributeur de gaz industriels AIR LIQUIDE Pour tout renseignement sur la disponibilité, n'hésitez pas à nous contacter.

Vous êtes à la recherche d’une entreprise pour fabriquer votre machine abrasive?

Nous maîtrisons parfaitement toutes les étapes de fabrication, pensez à TMUA.

Toute demande est réalisable, n’hésitez pas à nous contacter.

2 voies des Mineurs,

ZA Chambaret Sud – 43300 Langeac

TMUA fait partie du groupe SIBIM

Sibim est un groupe industriel regroupant quatre sociétés spécialisées chacune dans la machine spéciale, la sous-traitance industrielle et le négoce de produits abrasifs.

Doté d’investissements modernes et de plusieurs bureaux d’études spécialisés en mécanique et automatisme ou robotique, la force de propositions techniques et d’innovations a fait ses preuves dans des secteurs aussi variés que l’aéronautique, la maroquinerie de luxe, l’agroalimentaire ou la machine outil.